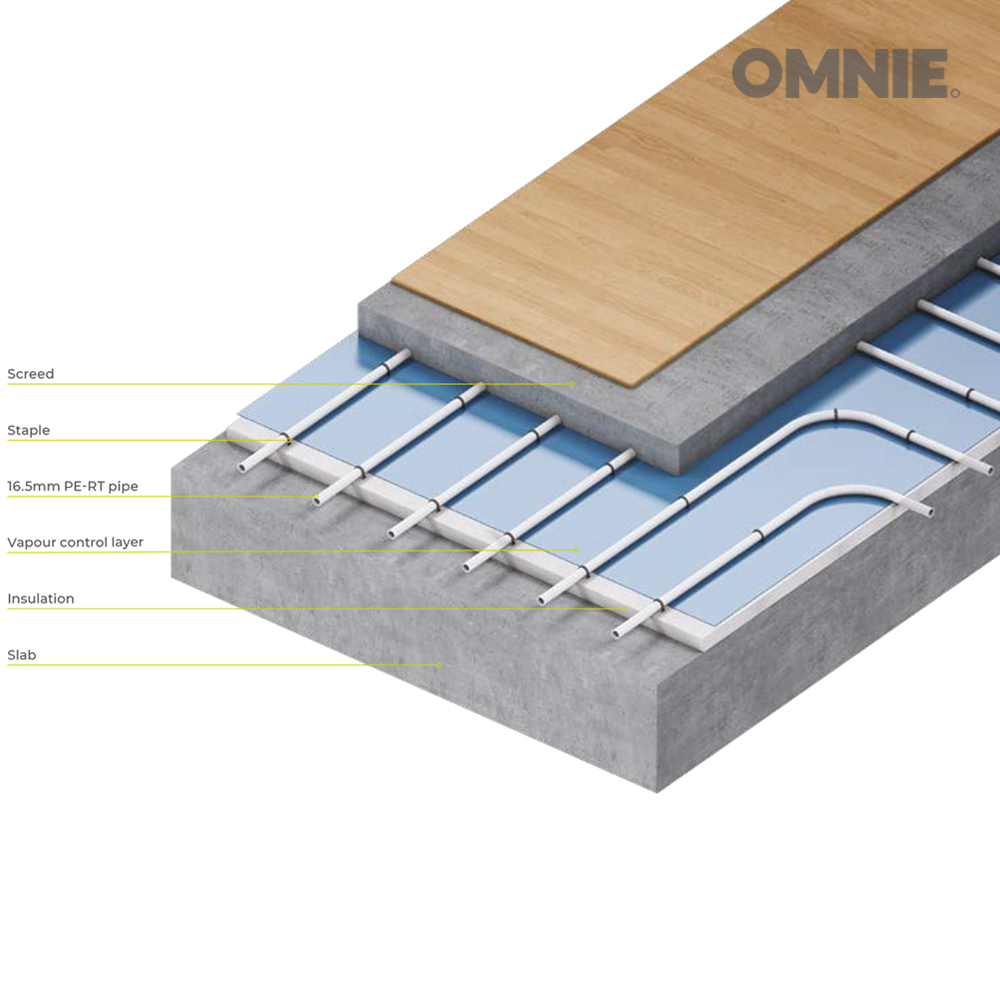

Staple System

| Introduction |

|---|

The staple system provides a quick, flexible and simple method of securing the underfloor heating pipework when laying a screed floor. The pipe is easily held using staples. The staples have a barbed end which fixes into the insulation. To speed up the process further a pipe stapler is available, making installation even easier and faster. In preparation for certain screeds, a polythene sheet/membrane may be required over the insulation prior to stapling the pipe. Please seek advice from insulation and screed manufacturer’s/suppliers. |

|

| Specification |

|---|

OMNIE Staple system using 16.5mm PE-RT pipe to DIN 4726 fixed using staples. Expansion foam to be installed around the perimeter of the room. The system to be designed, installed and commissioned to BS1264. LAYFAST – Speed up installation time. This product uses our multidirectional pipe channel system. |

|

| Technical Details | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Pipe Centres Screed Existing Slab Heat Outputs As a guide the heat outputs below are based on 16.5mm PE-RT pipe at 150mm centres with 65mm sand/cement screed laid over. Air Temperature = 20°C. (0.15 m²K/W = 1.5 TOG.) |

||||||||||||||||||||

|

||||||||||||||||||||

|