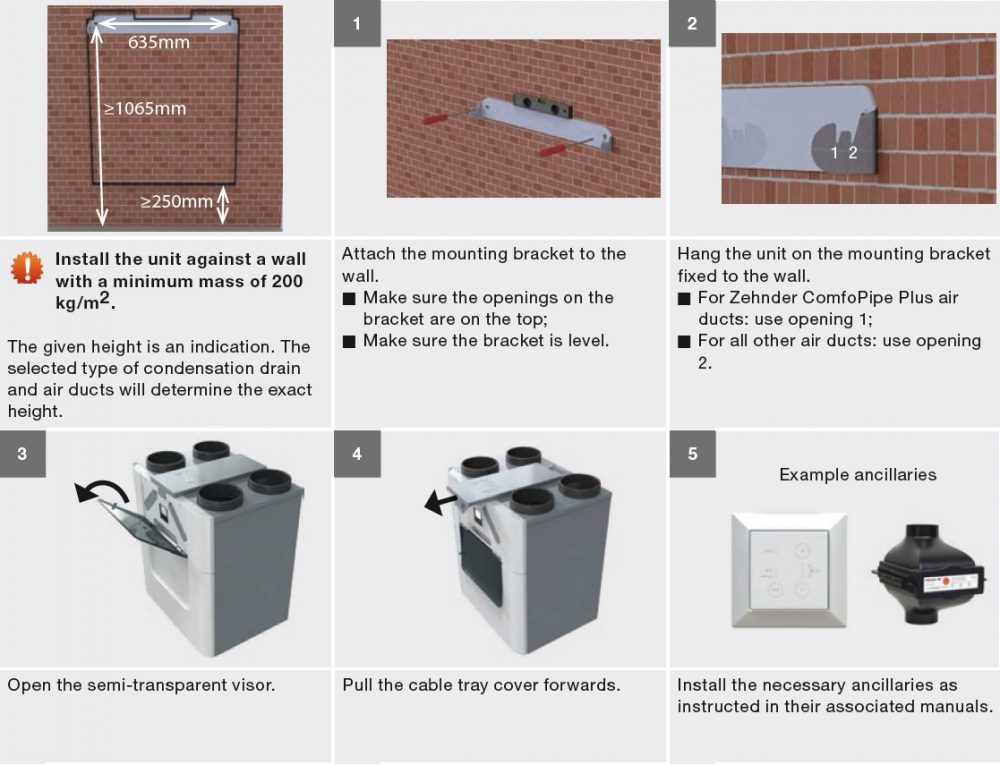

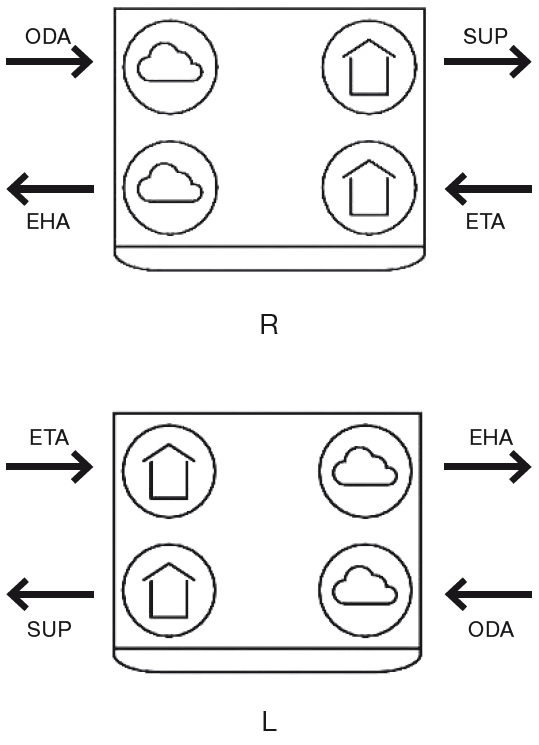

Installation of the CQ HRU (CQ 350/450 & 600)

| Installation on the wall |

|---|

|

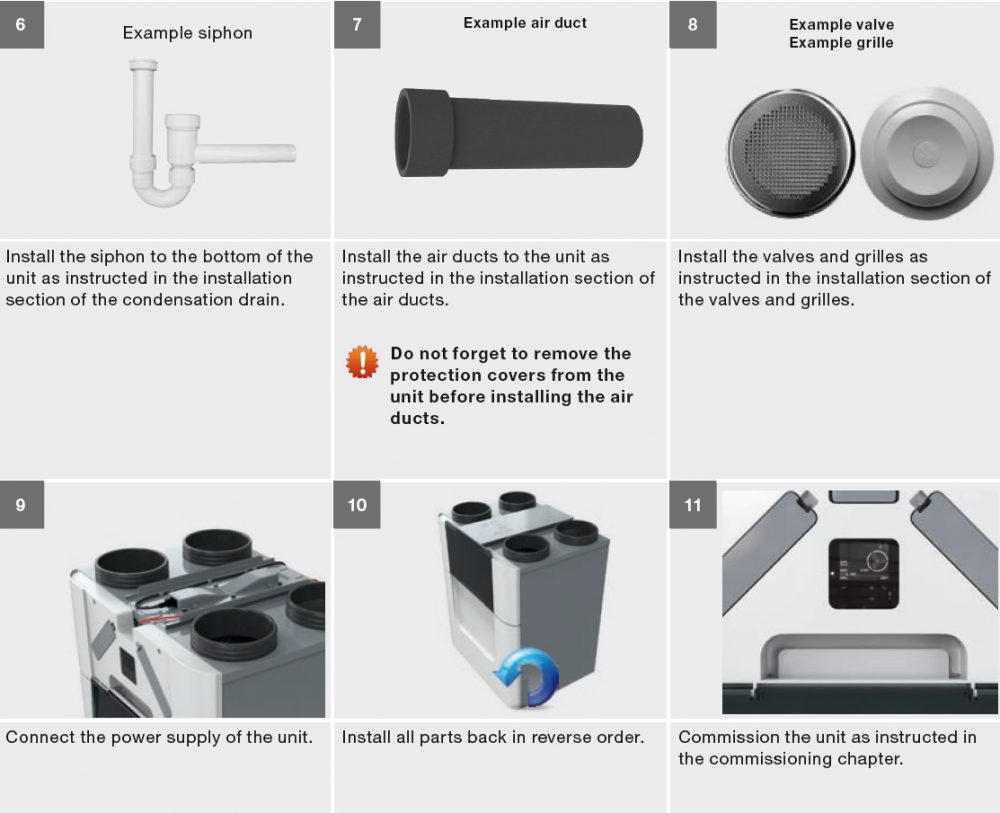

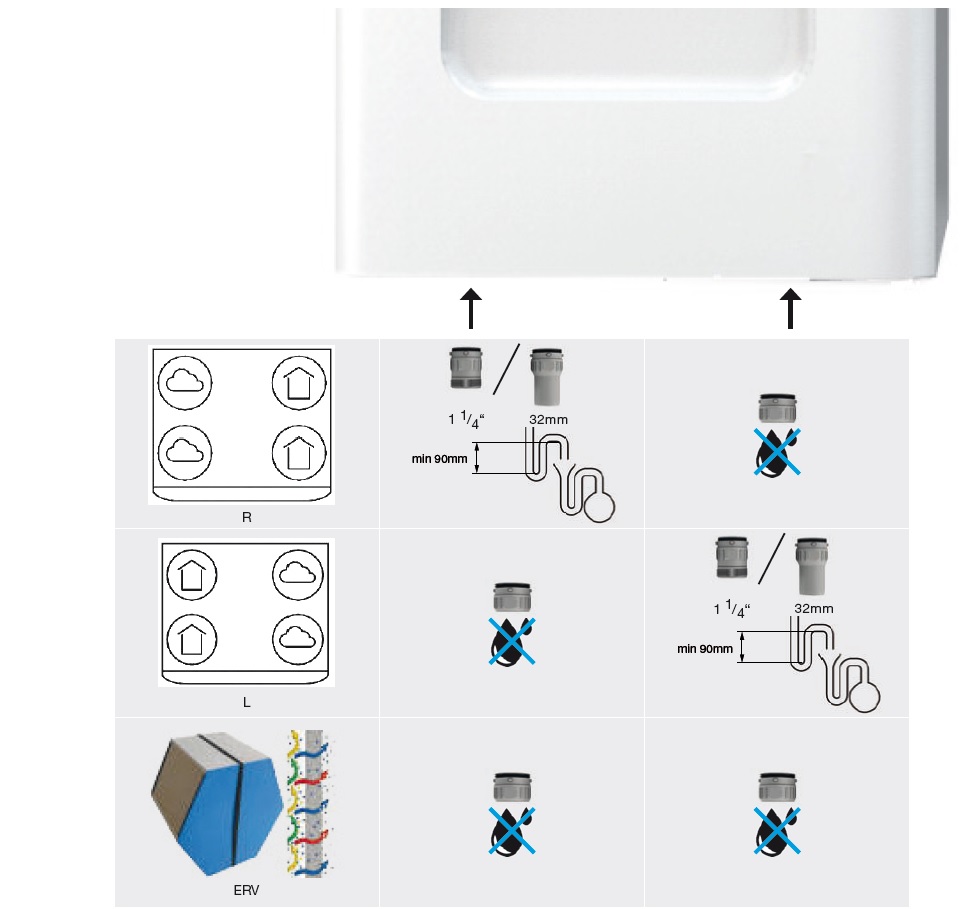

| Installation of the condensation drain |

|---|

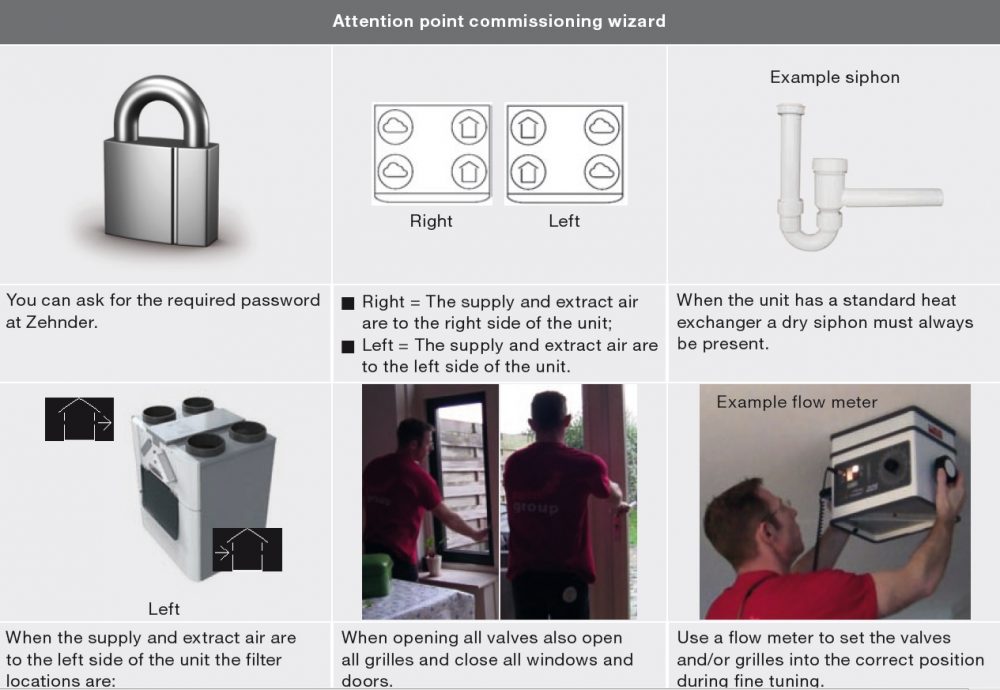

The condensation created by the unit must be drained off frost-free, at a gradient and incorporate an air seal. To drain the condensation from the unit, two bayonet connections are located on the bottom of the unit. These connections are not air tight. Thus it is necessary to close off these connections with the separately delivered sealing cap(s) or with a dry siphon. ⚠ Do not install a water lock (U-bend) on to the unit. On warm days the water will evaporate from the siphon. Enthalpy exchanger installed: When the unit is fitted with an enthalpy exchanger the humidity from the extracted air is partly transferred to the fresh supply air. In this case there is no need to condensate to be drained from the unit. When no dry siphon is installed, seal off both Omnie bayonet connections with the separately delivered condensation drain sealing caps. The unit is not airtight if these connections are left open. ☞ When desired you can always connect a dry siphon to a bayonet connection.

|

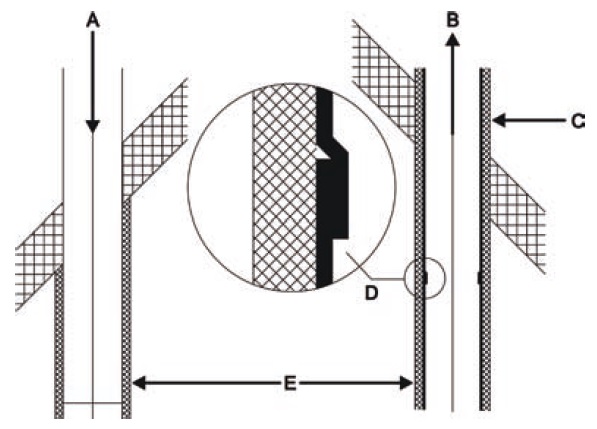

| Installation of the air ducts | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

The unit is supplied with a semi rigid system and manifold. When installing an Omnie air duct system read its installation instructions first. The next aspects must always be kept in mind during the installation of the air ducts: ⚠Always connect air ducts of at least 900mm to the unit before you connect the power to the unit. This ensures the motor cannot be touched while the unit is active.

|

||||||||||||||

|

||||||||||||||

|

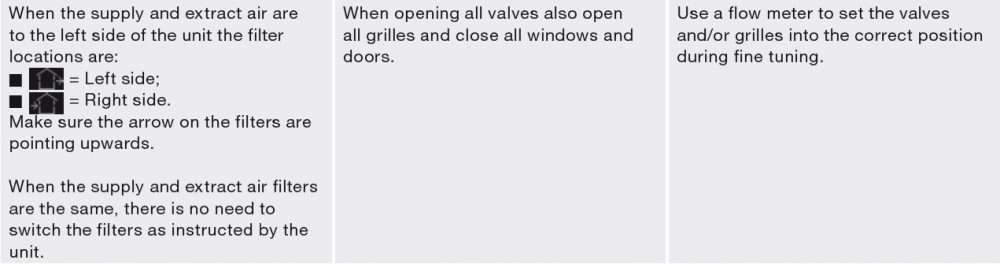

| Installation of the valves and/or grilles |

|---|

⚠ Do not obstruct these openings. For instance with furniture, draught excluders or deep pile carpet, as the airflow in the house will stagnate.

|

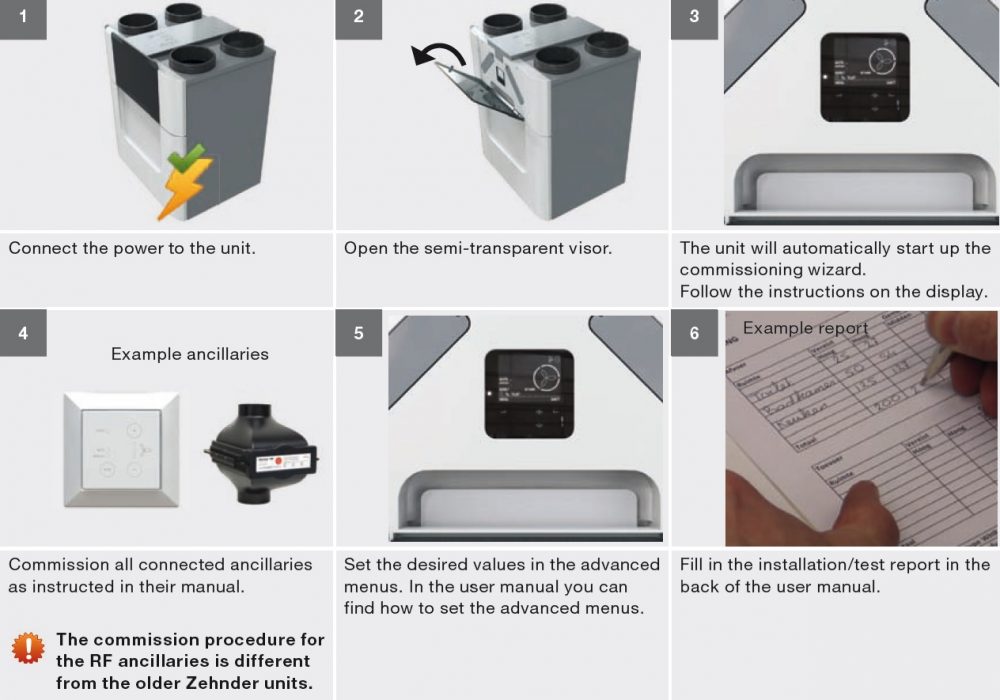

| Commissioning procedures |

|---|

Omnie recommends cleaning the air ducts before commissioning the unit when the dwelling is being occupied. This will prevent damage to the furniture from building dust blown out of the air ducts.

|