Pressure Testing the Underfloor Heating System

| Pressure Testing the Underfloor Heating System - Notes before you start |

|---|

Pressure test should be carried out by a suitably qualified person, following all current safety guidelines and rules. The results recorded on the form provided and a copy is sent back to OMNIE to validate the warranty. Pressure test the system before any screed or coverings are laid over the pipe. The test pressure should be maintained whilst screeding takes place and cures. It is also advisable to keep the system under pressure for non-screed systems while any structural floor layers/finishes are being laid. Circuits can be individually pressure tested if required but the system must be fully tested and recorded with all the UFH pipes connected to the manifold and the system is filled and purged of air. Please refer to the System filling instructions (IG UFH 27.1). OMNIE does not recommend air testing of its systems. Special care is necessary if the pressure testing is to take place in sub-zero temperatures, don’t leave any plain water in the system. Antifreeze/Inhibitor If you need further advice please call Customer Service team on 01392 36 36 05 or Email customer.service@omnie.co.uk |

| Stage 1 |

|---|

|

|

| Stage 2 |

|---|

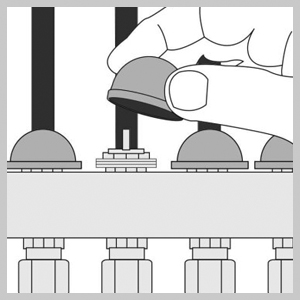

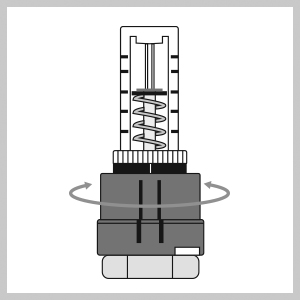

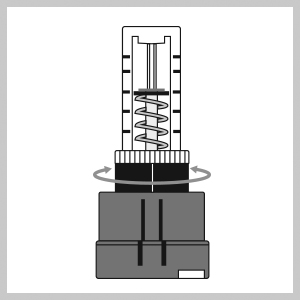

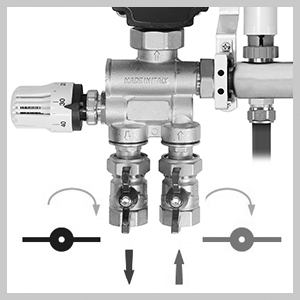

Remove caps or the actuators/regulators if fitted on the lower return arm of the manifold and ensure the circuit isolator valves/flow meters all are fully open on the upper flow arm. This is done by turning the red collars anti clockwise by hand until fully open.

|

| Stage 3 |

|---|

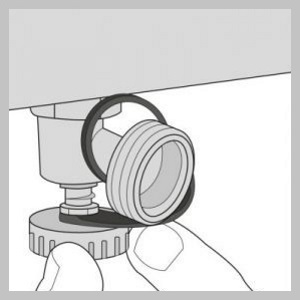

Connect a pressure test pump to the filling/drain valve on the upper flow arm of the manifold. Once connected open the valve fully anticlockwise using the square key on the cap. |

|

| Stage 4 |

|---|

Vent the system of any residual air then increase the pressure to 6 bar. Initially allow for a 15 minutes stabilisation period at 6 bar, if pressure drops increase back to 6 bar and maintain for a further 45 minutes. |

|

| Stage 5 |

|---|

If the pressure has dropped examine the pipework and manifold for possible leaks. It may be necessary to pressure test individual circuits to determine if there has been damage to a pipe. Resolve where necessary and repeat the pressure test. |

| Stage 6 |

|---|

Once the pressure is maintained consistently, record the results on the pressure test certificate. Have the test witnessed and certified by a third party. Fax, post or scan and return this form back to OMNIE to validate the warranty. |

|

UFH Pressure Test Form

|